Gator Battery Components

-

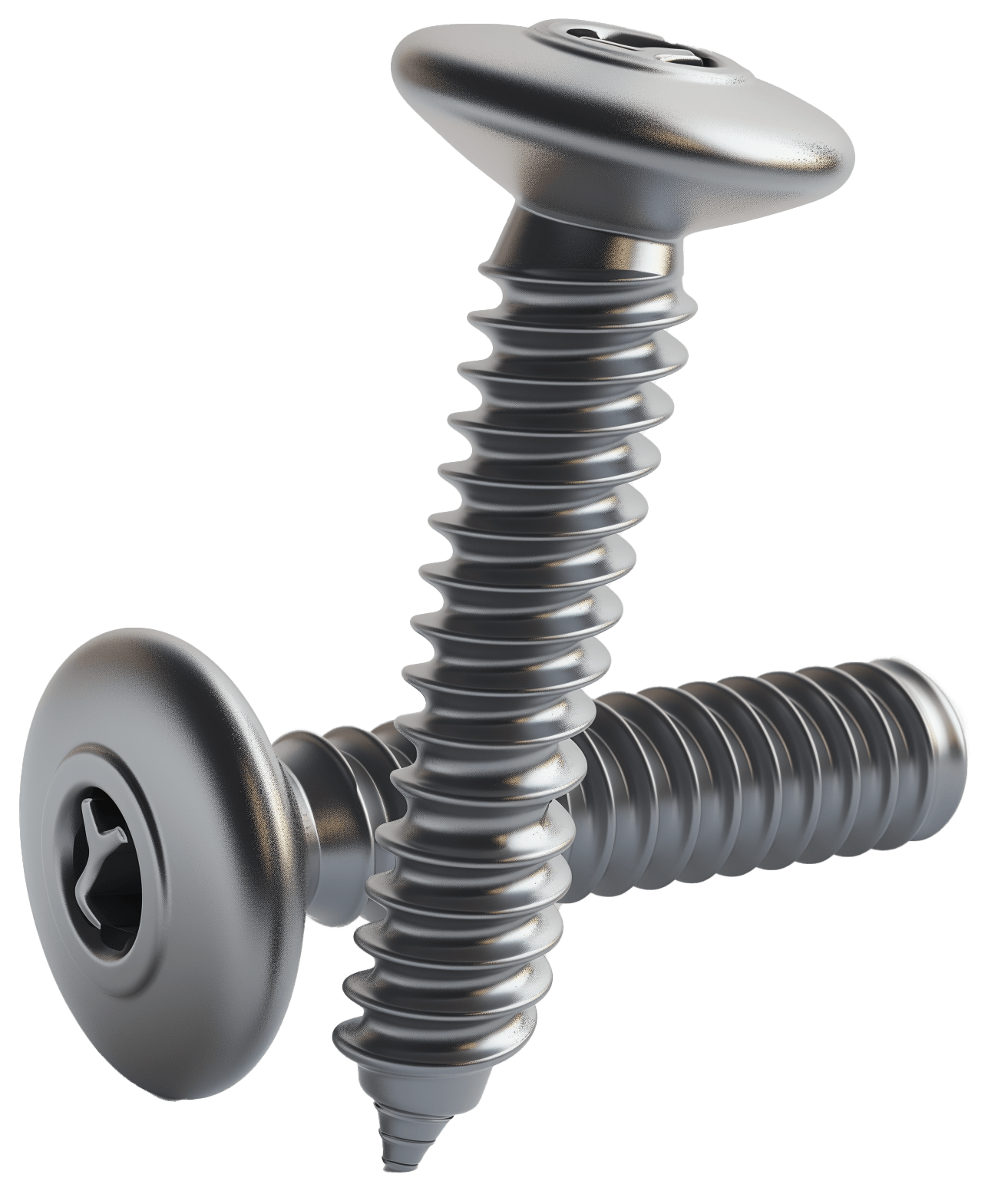

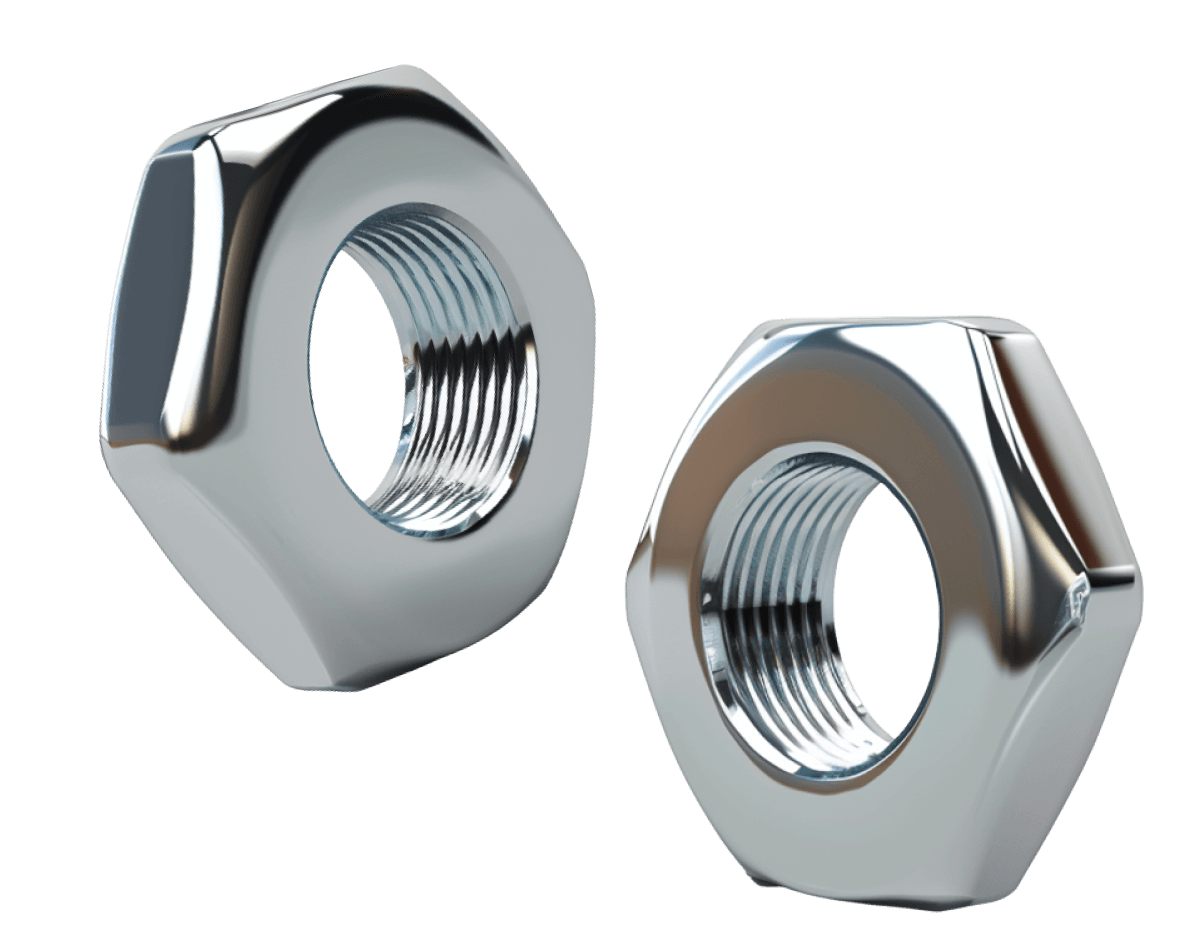

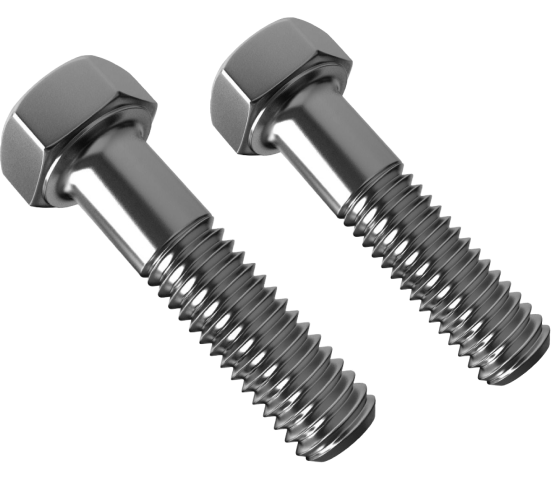

DIN, ASME, JIS, ISO, UNI, EU, BS, CSN, PN, GB

-

High & Low Temperature Durable

-

High Strength

-

Corrosion Resistant

-

Weathering Steel & Marine Grade

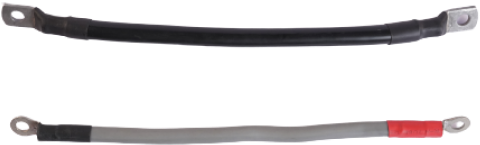

Charging Cable Connector

Materials

--

Surface Treatments

Copper / Tin

Battery Charging Link

Materials

SS316L

Surface Treatments

--

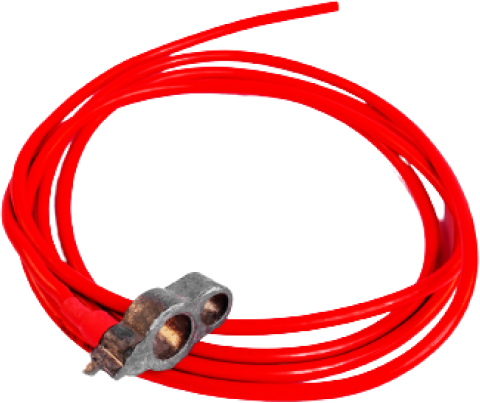

Universal Charging Link

Materials

Lead

Surface Treatments

--

Multimeter Probe

Materials

--

Surface Treatments

--

Battery Charging Link (Block Type)

Materials

Copper

Surface Treatments

Nickel / Tin

25Ah Battery Charging Link

Materials

SS316L

Surface Treatments

--

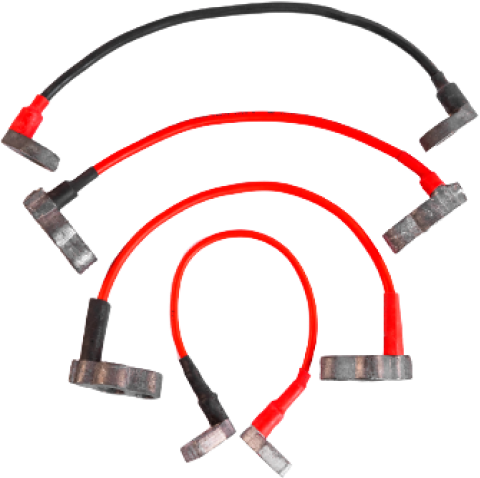

Battery Charging Link – for NS 70 pole

Materials

Lead

Surface Treatments

--

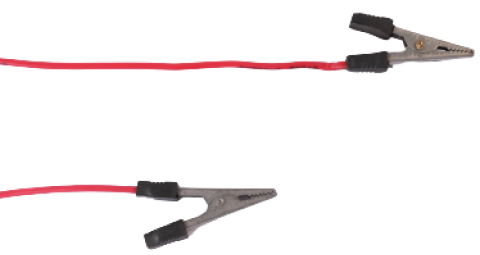

Crocodile Clips

Materials

SS316L

Surface Treatments

--

25Ah Charging Link

Materials

MS

Surface Treatments

Lead

What Makes

Gator Better?

End-to-End In-house Facilities & Infrastructure

Explore our end-to-end facilities for efficient fastener production - from design to quality control. Guaranteed top-notch products tailored to your specific needs.

Stringent Quality

Standards & Processes

Accredited to IATF 16949:2016, ISO 9001:2015, ISO 14001:2015, ISO 45001:2018, we prioritise excellence. We have a proven track record for high-quality shipment.

Customised

Products & Solutions

We go beyond standard parts and craft products meticulously to match your requirements. Precision, innovation and satisfaction guaranteed.

Optimised for

any JIT requirements

Backed by our own fleet of vehicles, we provide dedicated transportation for all your JIT requirements, ensuring efficient service.

Certifications

End-to-end top notch facilities

Our advanced facility utilises Cold Heading & Threading, Metal Stamping, Wire Processing, and Heat Treatment for precise, durable fasteners meeting the highest industry standards.

Our advanced electroplating plant automates surface treatments for Copper, Zinc, Lead, Tin, and Nickel coatings. Boosting corrosion resistance & aesthetics, our fasteners deliver lasting performance.

With advanced optical inspection systems, profile projectors, and comparators, our Inspection & Quality Control facility ensures fasteners meet strict standards and deliver flawless performance.

Our Customised Assembly facility uses an automated machine to check thread quality and torque, ensuring precise part assembly. This guarantees reliability and premium functionality of products.

Efficient in-house logistics streamline material flow, reduce lead times, and meet client demands precisely. Enhancing operations for seamless movement.